Konveyör Bandı 304 Metal Paslanmaz Çelik Spiral Tel Örgü Konveyör Bandı Yüksek Sıcaklık Zincir Bağlantı Bandı Gıda Endüstrisi İçin

Paslanmaz çelik zincirli konveyörler, korozyon direnci, hijyen, dayanıklılık ve sıcaklık toleransının kritik olduğu, zorlu taşıma uygulamaları için birinci sınıf bir seçimdir. İlk yatırım daha yüksek olsa da, uzun ömürlülükleri, düşük bakım ihtiyaçları (korozyona uğramış karbon çeliğine kıyasla) ve sıhhi standartlara uygunlukları, gıda, ilaç, kimyasallar ve zorlu endüstriyel ortamlar gibi sektörlerde onları oldukça uygun maliyetli çözümler haline getirir. Uygun kurulum, gerdirme, temizlik ve önleyici bakım, performanslarını ve ömürlerini en üst düzeye çıkarmanın anahtarıdır.

| Malzeme |

SS304, SS316, SS316L, SS430, Galvanizli tel, özelleştirilmiş |

| Spiral tel çapı |

0,5 mm - 3 mm, özelleştirilmiş |

| Çubuk tel çapı |

0,5 mm - 4 mm, özelleştirilmiş |

| Spiral aralığı |

5-50mm, özelleştirilmiş |

| Çubuk aralığı |

5-50mm, özelleştirilmiş |

| Genişlik |

Örgü bant genişliği (zincirsiz) / Konveyör bant genişliği (zincirli) |

| Uzunluk |

1m - 10m, özelleştirilmiş |

Avantajları:

1. Üstün Korozyon Direnci: Paslanmaya, kimyasallara, suya, buhara ve temizlik maddelerine karşı dayanıklıdır, bu da onu ıslak, nemli veya aşındırıcı ortamlar (gıda, kimyasal, deniz) için ideal hale getirir.

2. Yüksek Hijyen ve Temizlenebilirlik: Pürüzsüz, gözeneksiz yüzeyler bakteri üremesini engeller ve kolay temizlik sağlar. Gıda, içecek, ilaç ve tıbbi uygulamalar için önemlidir.

3. Yüksek Sıcaklık Dayanımı: Önemli ısı altında (örneğin, fırınlar, yıkama makineleri, sterilizatörler, dökümhaneler) mukavemetini ve bütünlüğünü korur.

4. Güç ve Dayanıklılık: Birçok alternatife göre ağır yüklere, darbelere ve aşındırıcı malzemelere daha iyi dayanır. Uzun hizmet ömrü.

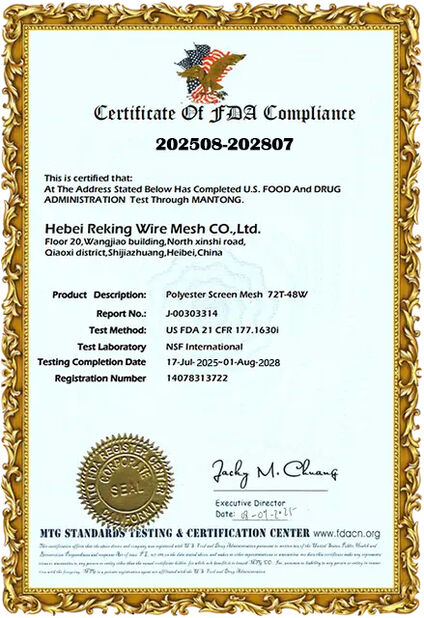

5. Hijyenik Tasarım: Katı hijyen düzenlemelerini (FDA, USDA, 3-A) karşılayarak, kalıntıların birikebileceği alanları en aza indirir.

6. Estetik Çekicilik: Zaman içinde temiz, profesyonel bir görünüm korur.

7. Oksidasyona ve Lekelenmeye Karşı Direnç: Dış mekanlarda veya oksidasyona eğilimli ortamlarda iyi performans gösterir.

Nasıl kullanılır:

1. Kurulum: Uygun hizalama ve tesviye sağlayarak sert çerçeveyi güvenli bir şekilde monte edin. Tahrik ünitesini (motor, şanzıman) ve kuyruk/toplama bölümünü kurun.

2. Zincir Gerdirme: Zinciri toplama mekanizmasını kullanarak doğru şekilde gerin – çok sıkı (aşırı aşınma) veya çok gevşek (kayma, raydan çıkma) olmamalıdır.

3. Yükleme: Ürünler tipik olarak zincir yüzeyine manuel olarak, besleyiciler aracılığıyla veya önceki ekipmandan yüklenir. Yükün kapasite dahilinde ve eşit olarak dağıtıldığından emin olun.

4. Çalıştırma: Tahrik sistemini çalıştırın. Zincirler, ürünü taşıyarak sürekli veya endeksleme (başlat/durdur) yoluyla parça boyunca hareket eder. Hız, tahrik aracılığıyla kontrol edilir.

5. Boşaltma: Ürünler, manuel olarak, yerçekimi yoluyla veya başka bir konveyöre, uçta (veya iticiler/saptırmalar aracılığıyla ara noktalarda) boşaltılır.

Temizlik ve Bakım:

Düzenli Temizlik: Su, buhar veya onaylı dezenfektanlar kullanın. Yüksek basınçlı yıkama yaygındır. Uygun drenaj sağlayın.

Yağlama: Gerekirse (bazı tasarımlar kendi kendini yağlayan zincirler kullanır veya kuru çalışır) gıda sınıfı veya uyumlu yağlayıcıları az miktarda kullanın. Kirlenmeden kaçının.

İnceleme: Zincir aşınmasını (gerilme), hasarlı bağlantıları, aşınmış dişlileri, uygun gerginliği, yatak durumunu ve çerçeve bütünlüğünü düzenli olarak kontrol edin.

Bileşen Değişimi: Arızaları önlemek için aşınmış zincirleri, dişlileri, kılavuzları ve yatakları derhal değiştirin.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!